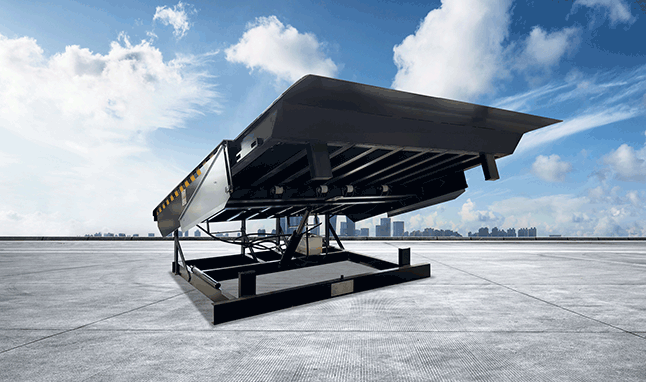

Telescoping lip dock leveler

Telescoping lip dock leveler is installed in logistics overside port. It acts as a bridge between the freight platform and truck. Lip can extend up to 1000mm. Telescoping lip dock leveler flexibly adapts to different height requirements of varioustrucks, In the course of loading and unloading, the exchange of the heat of the indoor and the outdoor hot and cold air is reduced, Telescoping lip dock leveler is recommended. The loading and unloading port industrial door can be completely closed. When the 20-foot container is loaded and unloaded, the opening direction of the container is perpendicular to the load- ing port, so it is convenient to use, and there is no need for transshipment again.